Understanding the Nitrogen Regulator

What is a Nitrogen Regulator?

A nitrogen regulator is a specialized device utilized to control the pressure and flow of nitrogen gas from a storage cylinder to various applications. It is a vital component in many industrial processes where nitrogen serves as an inert gas for purging, pressurizing, or cooling. The regulator functions by reducing the high pressure of the gas coming from the cylinder to a manageable level that is suitable for operation, ensuring safety and efficiency in the use of nitrogen.

Typically made from durable materials like brass or stainless steel, nitrogen regulators can be tailored for specific applications, helping maintain a consistent flow and pressure. For detailed guidelines and options, you can explore a range of nitrogen regulators available in different designs and specifications.

Importance of Nitrogen Regulators in Various Industries

Nitrogen regulators are critical in industries including food and beverage, pharmaceuticals, HVAC, and welding. In the food and beverage industry, they serve to maintain freshness by displacing oxygen in packaging. In pharmaceuticals, nitrogen is vital for preserving sensitive compounds and preventing contamination during manufacturing.

In HVAC systems, nitrogen plays a crucial role in pressure testing and system purging to ensure optimal performance without risk of contamination from atmospheric gases. Similarly, in welding applications, nitrogen is often used to provide a shielding atmosphere, protecting the weld from environmental elements that could potentially compromise integrity.

Components of a Nitrogen Regulator

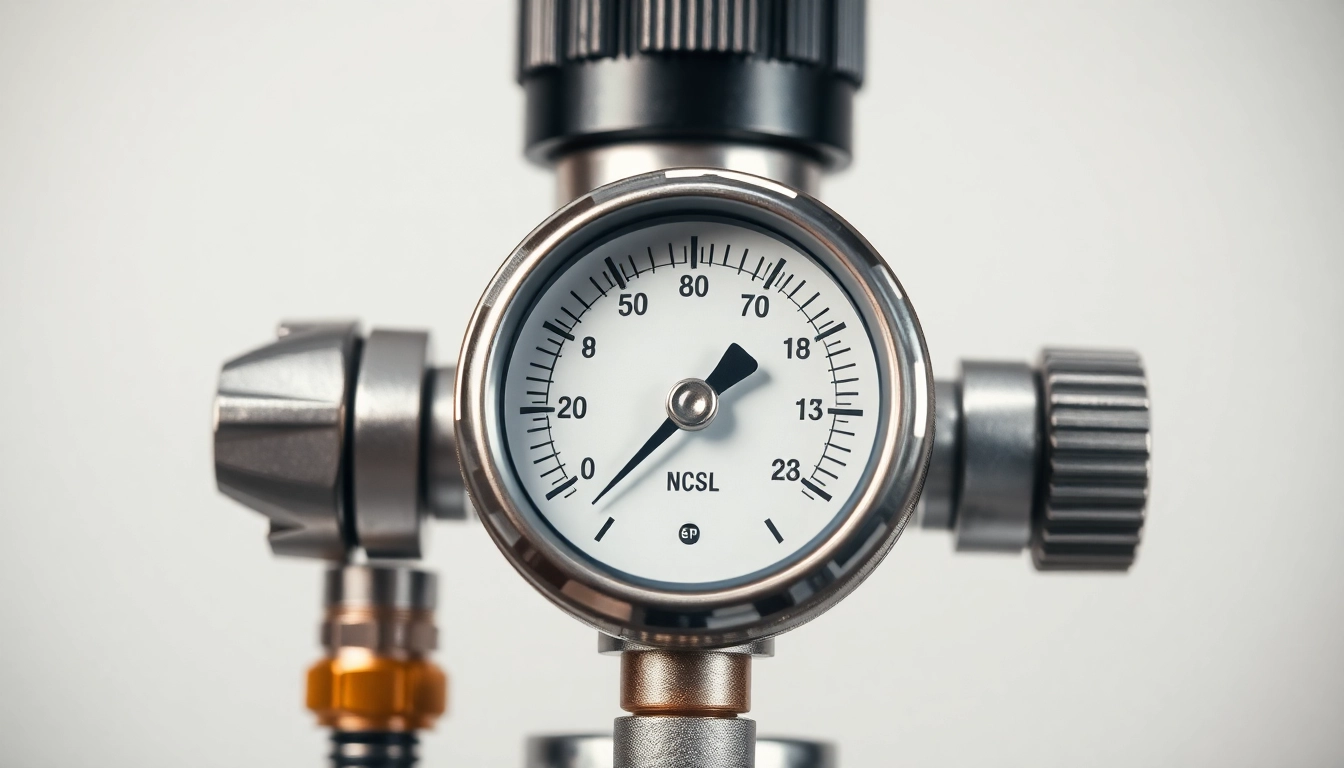

A typical nitrogen regulator consists of several key components:

- Inlet Connection: This is the connection where the nitrogen gas is introduced, usually from a cylinder. Common connections include CGA580.

- Pressure Adjustment Knob: This allows users to set the desired outlet pressure, adjusting the flow rate as required for specific applications.

- Outlet Port: This is where the regulated nitrogen is delivered to the application, typically fitted with hoses or fittings compatible with the intended system.

- Pressure Gauge: This component displays the current pressure levels in the system, which aids operators in monitoring performance and making necessary adjustments.

- Body and Housing: Typically made from heavy-duty materials that withstand high pressures, ensuring the regulator’s durability and safety in operation.

Types of Nitrogen Regulators

Fixed vs. Adjustable Nitrogen Regulators

Nitrogen regulators can be categorized into fixed and adjustable types based on their functionality. Fixed regulators provide a preset outlet pressure, which is beneficial for processes requiring constant, unchanging conditions. These are typically used in applications where the demand for nitrogen is stable, such as in certain types of packaging.

Adjustable regulators, on the other hand, allow users to modify the outlet pressure based on specific operational needs. This flexibility is advantageous in diverse applications that may vary in pressure requirements, such as in laboratory experiments or industrial processes where conditions can change rapidly.

High-Pressure vs. Low-Pressure Nitrogen Regulators

Another critical differentiation among nitrogen regulators is between high-pressure and low-pressure units. High-pressure regulators are designed to handle gas from high-pressure cylinders, often maintaining pressures upward of 3000 psi. They are used in applications like gas chromatography or for delivering nitrogen in bulk at elevated pressures.

Conversely, low-pressure nitrogen regulators serve applications that operate under lower pressures, typically below 200 psi. These are commonly used in food preservation or HVAC systems where reduced pressure is sufficient for operation without risking line integrity.

Applications of Different Nitrogen Regulators

The selection of a nitrogen regulator greatly depends on the specific application. For instance:

- Food and Beverage: Regulators with low-pressure settings are often used to preserve the quality of packaged goods by preventing oxidation.

- Manufacturing: High-pressure nitrogen regulators are crucial in processes that involve cooling or pressurizing machinery.

- Laboratories: Adjustable regulators are preferred in scientific environments where precise control over gas flow is paramount.

How to Choose a Nitrogen Regulator

Key Factors to Consider

Selecting the right nitrogen regulator involves assessing various factors including:

- Pressure Requirements: Understanding the required inlet and outlet pressures for your specific application will help in choosing between high-pressure and low-pressure regulators.

- Flow Rate: Determine the flow rate needed for your application. Some processes may require high flow rates, while others may need a more gradual delivery.

- Material Compatibility: Ensure the regulator is made from materials compatible with nitrogen and other substances it may come into contact with.

- Safety Features: Look for additional safety features like pressure relief valves, which can prevent accidents due to over-pressurization.

Common Pitfalls to Avoid

Choosing the wrong nitrogen regulator can lead to inefficiencies and potential hazards. Here are some common pitfalls:

- Buying a Regulator Without Understanding Application Needs: Failing to analyze specific operational requirements can result in inadequate performance.

- Ignoring Manufacturer Specifications: Always check the specifications to ensure compatibility and performance standards are met.

- Overlooking Maintenance Needs: Select a regulator that matches your capability to perform regular maintenance, which is vital for longevity and safe operation.

Recommended Specifications

When selecting a nitrogen regulator, consider the following recommended specifications:

- Pressure range: Ensure it covers the range required for your specific application.

- Material: Opt for stainless steel or brass for durability and resistance to corrosion.

- Gauge Accuracy: Choose regulators with accurate pressure gauges to maintain correct operational pressure consistently.

Installation and Maintenance of Nitrogen Regulators

Installation Guide for Safety

Proper installation of nitrogen regulators is crucial for safe and effective operation. Follow these steps for installation:

- Preparation: Ensure all connections, fittings, and hoses are clean and fit for use.

- Mounting: Securely mount the regulator to avoid movement or vibration during operation.

- Connect the Inlet: Attach the inlet connection to the nitrogen cylinder, taking care to follow manufacturer guidelines.

- Attach the Outlet: Connect the outlet to the application, ensuring secure and leak-proof fittings.

- Testing: Once installed, test for leaks by applying a leak detection solution or performing a pressure test before operational use.

Routine Maintenance Tips

To ensure longevity and reliable performance, routine maintenance of nitrogen regulators is essential. Here are key maintenance tips:

- Regular Inspections: Check for leaks, corrosion, or damage frequently to identify issues before they escalate.

- Clean Components: Keep the regulator clean and free from dirt or debris that might obstruct function.

- Replace Worn Parts: Address any worn seals or gauges immediately to maintain operational integrity.

Signs of Damage or Failure

Operators should be vigilant for signs indicating potential damage or failure in nitrogen regulators, including:

- Inaccurate Pressure Readings: Fluctuations or consistent deviation from set pressure can signal problems.

- Hissing Sounds: Unusual noises may indicate a leak, necessitating immediate inspection.

- Physical Damage: Any visible signs of wear, such as cracks or dents, require attention to prevent unsafe operation.

Frequently Asked Questions About Nitrogen Regulators

What is the Purpose of a Nitrogen Regulator?

A nitrogen regulator serves to control the flow and pressure of nitrogen gas coming from a cylinder, allowing operators to use nitrogen safely and effectively in various applications, such as purging, pressurizing, and cooling.

How do Nitrogen Regulators Differ from CO2 Regulators?

Nitrogen regulators and CO2 regulators are distinct in function due to the physical properties of the gases they control. Nitrogen, being a gas, requires a regulator capable of handling higher pressures compared to CO2, which is dispensed as a liquid and necessitates a different pressure range for effective operation.

Where to Buy Reliable Nitrogen Regulators?

Reliable nitrogen regulators can be sourced from specialized suppliers, industrial gas distributors, or online platforms that focus on welding and gas supply equipment. Always prioritize vendors known for quality assurance and customer service to ensure you receive a product that meets your operational needs.